Unlocking Global Opportunities with Door Assembly Machines at the 137th Canton Fair

The recent 137th Canton Fair has set a remarkable precedent for global business interactions, particularly in the door assembly machine industry. Held in Guangzhou, this year's fair attracted an unprecedented number of overseas buyers, with 288,938 attendees from 219 countries and regions, marking a 17.3% increase compared to the previous event. The fair was a platform not only for showcasing innovations but also for forging significant trade connections, evidenced by an intention to export amounting to a staggering $25.44 billion, reflecting a 3% growth. As the demand for efficient and automated solutions in manufacturing escalates, door assembly machines are poised to play a crucial role in fulfilling global market needs. The opportunities presented at the fair signal a thriving future for businesses engaged in this sector, as the forthcoming 138th Canton Fair prepares to further enhance these interactions in October.

Read more »

By:Oliver - May 26, 2025

By:Oliver - May 26, 2025

Elevating Global Standards: How Our Door Jamb Machines Redefine Quality in Manufacturing

In today's competitive manufacturing landscape, quality standards are more crucial than ever, and the efficiency of production processes significantly impacts overall output. According to a recent report by the National Association of Manufacturers, 70% of manufacturers are investing in advanced technologies to enhance both product quality and operational efficiency. Among these technological advancements, the Door Jamb Machine stands out as a pivotal innovation. This machine not only streamlines the production of door frames but also ensures precision and consistency that meet the highest industry standards. As manufacturers worldwide strive for excellence, integrating a modern Door Jamb Machine into their operations symbolizes a commitment to elevating global standards, ultimately redefining what quality means in manufacturing.

Read more »

By:Evelyn - May 21, 2025

By:Evelyn - May 21, 2025

7 Amazing Facts About Used Prehung Door Machinery You Need to Know

In the world of door manufacturing and installation, understanding the tools and machinery involved is crucial for ensuring quality and efficiency. One such vital equipment is used prehung door machinery, which plays a significant role in streamlining the production process and enhancing the overall quality of the finished product. This blog aims to unveil seven amazing facts about used prehung door machinery that every door manufacturer and enthusiast should know. From the remarkable durability and versatility of these machines to their cost-effectiveness and environmental benefits, we will explore how investing in used machinery can yield significant advantages. As the demand for custom doors continues to rise, being informed about the capabilities and innovations in used prehung door machinery can empower businesses to optimize their operations and stay ahead in a competitive market. Join us as we delve into these fascinating insights that highlight the importance of embracing quality machinery in the door industry.

Read more »

By:Oliver - May 16, 2025

By:Oliver - May 16, 2025

8 Essential Door Manufacturing Machines to Elevate Your Production Efficiency

In the competitive landscape of the manufacturing industry, enhancing production efficiency is paramount for any door manufacturing business aiming to thrive. The right set of tools can make all the difference, particularly when it comes to streamlining processes and improving the quality of the final product. This is where specialized Door Manufacturing Machines come into play. These advanced technologies not only speed up production times but also ensure that each door meets the highest standards of precision and durability.

From automated cutting systems to innovative assembly lines, a variety of machines exist to cater to the diverse needs of door production. In this blog, we will explore eight essential Door Manufacturing Machines that can significantly elevate your production efficiency. By integrating these machines into your workflow, you can optimize operations, reduce labor costs, and ultimately enhance your product offering, keeping your business ahead of the competition. Join us as we delve into the machinery that can transform your production capabilities and set a new standard in door manufacturing.

Read more »

By:Evelyn - May 14, 2025

By:Evelyn - May 14, 2025

Exploring the Benefits of Investing in Pre-Owned Door Manufacturing Machinery for Global Buyers

In recent years, the global door manufacturing industry has witnessed significant growth, with the market projected to reach USD 76.74 billion by 2025, according to a report by Grand View Research. This growth trajectory is prompting many manufacturers to explore cost-effective solutions, including the acquisition of used door shop equipment. Investing in pre-owned machinery not only helps reduce initial capital expenditures but also allows companies to maintain competitive pricing in a rapidly evolving market. Industry data suggests that manufacturers can save up to 50% compared to purchasing new equipment, thereby enhancing their operational efficiency and profitability.

Moreover, as sustainability becomes a central focus for businesses worldwide, the use of used door shop equipment presents an environmentally friendly option that aligns with contemporary manufacturing practices. As highlighted in a report from the Manufacturing Institute, nearly 92% of manufacturers recognize the importance of sustainability in their operations. By investing in refurbished machinery, global buyers can contribute to waste reduction while obtaining high-quality equipment that meets their production demands. This blog will delve into the myriad benefits of utilizing pre-owned door manufacturing machinery, exploring how it can enhance operational capabilities and foster sustainable practices in the industry.

Read more »

By:Oliver - May 12, 2025

By:Oliver - May 12, 2025

Comprehensive Insights into Frame Assembly Machines for Global Buyers

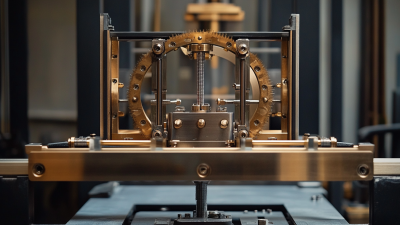

In recent years, the manufacturing landscape has been rapidly evolving, with automation technologies gaining prominence across various industries. According to a report by MarketsandMarkets, the global assembly machine market is expected to grow from $25 billion in 2021 to $39 billion by 2026, reflecting an average annual growth rate of 9.5%. This surge in demand is driven by the increasing need for efficiency and precision in manufacturing processes. Within this context, the Frame Assembly Machine has emerged as a critical component, facilitating the systematic assembly of frames for a wide range of products, from automobiles to electronic devices.

The Frame Assembly Machine not only enhances production speed but also significantly reduces labor costs and minimizes errors, making it an indispensable asset for manufacturers worldwide. A study by Grand View Research highlights that advancements in automation and robotics are set to reshape assembly line functionalities, paving the way for more advanced frame assembly solutions. As global buyers seek to optimize their manufacturing capabilities, understanding the intricacies of Frame Assembly Machines becomes essential. This blog aims to provide comprehensive insights into these machines, addressing their features, benefits, and the factors influencing their adoption in the competitive manufacturing environment.

Read more »

By:Evelyn - May 9, 2025

By:Evelyn - May 9, 2025

Innovative Solutions for Your Production Line with Advanced Door Machines

In the ever-evolving landscape of manufacturing, the push for efficiency and precision is more crucial than ever. One pivotal element in optimizing production lines is the integration of advanced technology, particularly through the use of specialized equipment like the Door Machine. This innovative machinery not only enhances the speed of production but also ensures the quality and consistency of the final products. As industries strive to meet increasing demands, exploring how these advanced Door Machines can transform the workflow becomes essential.

The implementation of advanced Door Machines presents a unique opportunity for manufacturers to streamline their operations while reducing labor costs and minimizing errors. These machines are designed to automate various processes in door production, allowing businesses to maintain a competitive edge. In this blog, we will delve deeper into the innovative solutions offered by state-of-the-art Door Machines and how they can revolutionize your production line, making it more efficient and responsive to market needs. Whether you're a small workshop or a large manufacturing plant, understanding the potential of these machines could be the key to unlocking new levels of productivity and success.

Read more »

By:Olivia - May 7, 2025

By:Olivia - May 7, 2025

Transform Your Production Line: Unleashing the Power of Innovative Casing Machines for Global Manufacturers

In today's fast-paced manufacturing environment, efficiency and adaptability are paramount for global manufacturers seeking to maintain a competitive edge. The increasing demand for customized packaging solutions and streamlined operations has put a spotlight on advanced machinery, particularly Casing Machines. According to a report by Smithers, the global packaging machinery market is projected to reach $50 billion by 2024, with Casing Machines playing a critical role in meeting the needs of diverse industries, including food, beverage, pharmaceuticals, and consumer goods. These innovative machines not only enhance production speed but also improve packaging accuracy and reduce material waste.

As manufacturers strive for automation and agility in their production lines, the integration of cutting-edge Casing Machines has become a game-changer. A study by MarketsandMarkets indicates that the automation in manufacturing is expected to grow at a CAGR of 9% from 2021 to 2026, with packaging automation being a significant contributor. By investing in state-of-the-art Casing Machines, companies can ensure operational efficiency, higher product quality, and lower labor costs. Embracing these advancements allows manufacturers to adapt swiftly to market demands, ultimately transforming their production lines into agile, sustainable operations ready to meet the challenges of the global marketplace.

Read more »

By:Oliver - May 6, 2025

By:Oliver - May 6, 2025

Revolutionizing Interior Door Manufacturing: Top 2025 Tech Advances and How to Leverage Them

As we move closer to 2025, the interior door manufacturing industry is on the brink of a technological revolution that promises to redefine efficiency, customization, and sustainability. According to a recent report by the Freedonia Group, the demand for interior doors is expected to grow at an annual rate of 4.6%, driven by a resurgence in residential construction and home renovation projects, as well as a rising trend towards personalized living spaces. This shift highlights the urgent need for manufacturers to adopt cutting-edge technologies, particularly Interior Door Machines, that streamline production processes and enhance product quality.

In this rapidly evolving market, leveraging advanced machinery can significantly improve the competitive edge for manufacturers. A study from IBISWorld indicates that companies investing in automation and sophisticated manufacturing techniques see a potential increase in productivity by up to 30%. By embracing innovations such as computer numerical control (CNC) machines, artificial intelligence, and smart manufacturing processes, interior door manufacturers can not only meet the growing consumer demands for customization and efficiency but also contribute to sustainability goals by reducing waste and energy consumption. As we delve into the top technological advances expected by 2025, it's crucial for industry players to understand how to effectively integrate these developments into their operations.

Read more »

By:Evelyn - May 6, 2025

By:Evelyn - May 6, 2025

Unlocking the Secrets of High Efficiency Door Machines and How to Maximize Their Performance

In the world of manufacturing and construction, high efficiency door machines play a pivotal role in optimizing productivity and ensuring superior quality in door production. As the demand for customized and high-performance doors continues to rise, understanding the intricacies of door machines becomes essential for manufacturers looking to stay competitive. These sophisticated machines can streamline workflows, reduce waste, and enhance precision, but unlocking their full potential requires knowledge of their features and effective operational strategies.

This blog aims to explore the essential elements that contribute to the performance of door machines. By delving into best practices for setup, maintenance, and operation, we will uncover the secrets to maximizing their efficiency. Whether you're a seasoned professional or new to the industry, this comprehensive guide will provide you with valuable insights to elevate your door production processes, ensuring that you harness the power of door machines to their fullest extent.

Read more »

By:Oliver - May 2, 2025

By:Oliver - May 2, 2025

Comprehensive Insights for Sourcing Prehung Door Machines Globally

In the rapidly evolving landscape of the global manufacturing industry, the demand for efficient and high-quality production equipment has surged significantly. According to a report by MarketsandMarkets, the global wood door market is projected to reach USD 15.87 billion by 2025, growing at a CAGR of 4.3%. This growth is driven by the increasing popularity of prehung doors, which not only enhance aesthetic appeal but also improve installation efficiency. Consequently, the sourcing of Prehung Door Machines has become a crucial aspect for manufacturers seeking to optimize their production lines and meet rising customer expectations.

Furthermore, the shift towards sustainable building practices and the use of eco-friendly materials is shaping the sourcing strategies for machinery in this sector. The International Door Association reports that prehung doors account for a significant portion of door sales, emphasizing the importance of investing in advanced technology to manufacture these products efficiently. As businesses navigate the complexities of sourcing Prehung Door Machines globally, it is imperative to understand market trends, technological advancements, and the competitive landscape to make informed decisions. This blog aims to provide comprehensive insights into the factors influencing the global sourcing of Prehung Door Machines, guiding manufacturers towards achieving operational excellence and sustainability.

Read more »

By:Oliver - May 1, 2025

By:Oliver - May 1, 2025

Exploring the Unique Features and Applications of Door Lite Cutters: A Comprehensive Buying Guide

When it comes to enhancing the functionality and aesthetic appeal of doors, Door Lite Cutters emerge as essential tools for both professionals and DIY enthusiasts. These specialized instruments are designed to create precise openings in doors, allowing for the installation of glass lites that enhance natural light while maintaining privacy and security. In an era where design versatility and craftsmanship are highly valued, understanding the unique features of Door Lite Cutters can significantly impact the outcome of your project. This guide aims to explore the intricacies of these tools and provide insights into their various applications.

Navigating the array of Door Lite Cutters available on the market can be daunting, especially for those unfamiliar with their specifications and uses. From different cutting techniques to material compatibility, each cutter offers distinct functionalities that cater to specific requirements. In this comprehensive buying guide, we will delve into the critical aspects you need to consider when selecting a Door Lite Cutter, ensuring that you choose the right tool for your next project. Whether you're upgrading your home’s entryways or working on commercial installations, this information will empower you to make informed decisions that elevate your craftsmanship.

Read more »

By:Oliver - April 29, 2025

By:Oliver - April 29, 2025

Unlocking the Potential of Interior Door Machines with Key Technical Specifications and Best Practices

The interior door manufacturing industry is experiencing significant transformation, driven by advancements in technology and an increasing demand for efficiency and precision. According to a recent report from MarketsandMarkets, the global market for woodworking machinery, including Interior Door Machines, is projected to reach USD 12.5 billion by 2025, growing at a compound annual growth rate (CAGR) of 5.3%. This surge highlights the pivotal role that specialized machinery plays in enhancing productivity and ensuring high-quality output within the competitive landscape of interior door production.

To fully capitalize on this growth, manufacturers must focus on understanding the key technical specifications and best practices associated with Interior Door Machines. These machines not only streamline the manufacturing process but also contribute to the customization and versatility that modern consumers demand. As noted by the International Woodworking Fair, integrating cutting-edge technologies such as automation and CNC capabilities allows manufacturers to optimize their workflows and reduce lead times while maintaining craftsmanship quality. This blog will delve into the essential features and operational insights that can unlock the full potential of Interior Door Machines, positioning manufacturers to thrive in a rapidly evolving market.

Read more »

By:Oliver - April 28, 2025

By:Oliver - April 28, 2025

Exploring Industry Solutions with Door Lite Cut Out Machine What It Brings to Your Production Line

In the dynamic landscape of the manufacturing industry, efficiency and precision are paramount. The increasing demand for custom-designed doors in sectors such as residential construction and commercial development has pushed manufacturers to innovate their production processes. According to a recent report by IBISWorld, the door manufacturing industry is projected to grow at an annual rate of 3.1% over the next five years, highlighting the need for advanced machinery that can keep pace with this growth. Enter the Door Lite Cut Out Machine, a revolutionary tool that streamlines the production of door lite cutouts, enhancing both speed and accuracy in fabrication.

The Door Lite Cut Out Machine not only addresses the urgency for greater throughput but also caters to the increasingly specific design requirements of contemporary architecture. A study by MarketsandMarkets indicates that the global market for architectural doors is expected to reach $22.9 billion by 2025, underscoring the crucial role of cutting-edge equipment in meeting customer demands. By integrating a Door Lite Cut Out Machine into the production line, manufacturers can not only optimize their workflow but also ensure that they remain competitive in this rapidly evolving market.

Read more »

By:Oliver - April 27, 2025

By:Oliver - April 27, 2025

Understanding the Technical Specifications of Door Assembly Machines for Optimal Procurement Decisions

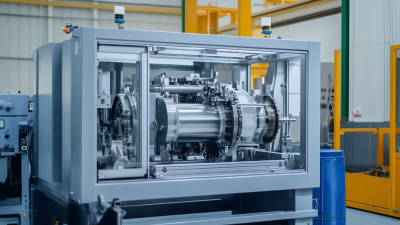

Selecting the right facility equipment stands important in the fast-changing world of manufacturing. The door assembly machine, which affects operational efficiency and product quality in the production line, cannot be overlooked. According to a recent Global Market Insights report, the door manufacturing market is poised to amount to $108 billion by the year 2026, as a result of rising demand for energy efficiency and aesthetically pleasing openings in both residential and commercial applications. To comply with market demand and regulatory requirements now and in the near future, manufacturers have to streamline their processes, which makes investment in modern door assembly machines an absolute necessity.

Besides, as user-friendly automated design and technical integration are more and more emphasized, newer designs and configurations for door assembly machines will commence. Freedonia Group states that automation demand in building construction and manufacturing will rise to over $20 billion by the year 2025, thus revealing a deep shift toward more modern production techniques. At the procurement end, having good knowledge of the technical features and operating capacities of any door assembly machine becomes instrumental in decision-making, which would then translate into massive cost savings and productivity gains. This blog intends to shed light on the relevant technical specifications of door assembly machines to make available informed decisions to manufacturers that complement their strategic objectives.

Read more »

By:Oliver - April 25, 2025

By:Oliver - April 25, 2025